Manonyeletso a Katoloso / Mahokelo a Katoloso ea Lesela

Tšebeliso ea Manonyeletso a Katoloso ea Lesela le sa Metal

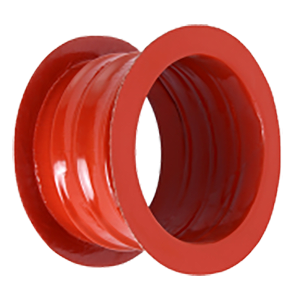

Manonyeletso a Katoloso ea Lesela le Senyehileng a nang le li-revers ke mofuta o mocha oa manonyeletso a se nang tšepe.Melemo e tloaelehileng ke e bobebe, e bobebe, ea hermetic, mocheso o phahameng oa ho sebetsa, anti-corrosive, sekhahla se seholo sa matšeliso le ho kenya habonolo.Li loketse bakeng sa khokahano e feto-fetohang lipakeng tsa libapali tse fapaneng tsa moea, li-ducts le liphaephe;e ka lefella deformation ea mocheso oa pipework le ho lokolla khatello ea lipeipi;fokotsa kapa ho fokotsa ho sisinyeha ha liphaephe;le ho etsa hore ho hlongoa tsamaiso eohle ho be bonolo.

Manonyeletso a Katoloso ea Lesela le Kokotehileng a fapane le a tloaelehileng ao e seng a tšepe.E entsoe ka lera le le leng kapa lihlopha tse ngata tsa rabara le masela, laminated tlas'a mocheso o phahameng le khatello;li-revers li fetoloa le ho bōptjoa hanngoe ka theknoloji e khethehileng, e fapaneng le mosebetsi oa matsoho bakeng sa ho hlahisa manonyeletso a tloaelehileng a ho atolosa---- ho khomarela, ho roka, ho koahela le ho tobetsa flange.'Me lithekniki tse khethehileng li etsa hore manonyeletso a rona a katoloso a hlōle lintlha tse fokolang tsa manonyeletso a tloaelehileng a kang laminated e sa tieang, eseng ea hermetic, e lutlang, e boima, e thata bakeng sa ho kenya le ho boloka.

Manonyeletso a Katoloso ea Lesela le Senyehileng a hokahana le li-flange ka lera la eona la rabara holim'a li-revers, khokahano e na le hermetic haholo;'me e ka boloka khatello ea ho sebetsa ea max 2MPa.The axial compression ratio, radial le rotational shifting e molemo haholo ho feta maqhama a tloaelehileng a ho atolosa.Manonyeletso a rona a Katoloso ea Lesela le Senyehileng a loketse haholo bakeng sa libapali tsa moea, liphaephe ho fokotsa ho sisinyeha ha sistimi, lerata le khatello ea maikutlo.Ke likarolo tse ntle ka ho fetisisa tseo u lokelang ho ba le tsona bakeng sa sistimi ea hau.

Re sebelisa mefuta e fapaneng ea masela ho etsa maqhama a katoloso ho latela litlhoko tsa bareki ba rona le maemo a ts'ebeliso, joalo ka rabara ea silicon, rabara ea fluorine, Ethylene-Propylene-Diene Monomer(EPDM).

E khothalelitsoeng Kopo

● Indasteri ea tšebetso

● Indasteri ea peterole

● Indasteri ea lik'hemik'hale

● Indasteri ea meriana

● Mecha ea litaba e chefo, e kotsi, ea lik'hemik'hale

● Mesaletsa le ho chesoa ha litšila

● Calcination

● Phokotso

● Indasteri ea oli le khase

● Theknoloji ea ho hloekisa

● Theknoloji ea setsi sa motlakase

● Indasteri ea pampiri le pampiri

● Ho hlahisa le ho sebetsa ka tšepe

● Indasteri ea samente

● Likotopo tsa khase ea flue

● Mehaho ea metsi a belisang le liphahlo

● Ho kenella ka lipeipi

● Mela ea tšebetso

● Mekotla

● Liindasteri tse nang le litlhoko tse phahameng

Melemo

● Ho fokotsa mesi ea tšilafalo

● Tšebetso e sireletsehileng

● Phokotso e kholo ea tšebeliso ea matla a mantlha

● Bophelo bo bolelele ba tšebeletso, ho apara ka tlaase

● Nako ea ho phomola e reriloeng esale pele

● E fumaneha e le puseletso litsamaisong tse teng

● Ho tenyetseha habonolo

● Ho hanyetsa lik'hemik'hale tse phahameng

● Ho fokotsa mocheso

● Matla a fokolang a ho arabela

※ E etselitsoe ho lumellana le maemo a sebele a ho sebetsa le lisebelisoa ha u li kopa.

| Thepa ea Lesela | Mesebetsi ea bopaki ba boemo ba leholimo | Mesebetsi ea 'mele | Mesebetsi ea lik'hemik'hale | mocheso o sebetsang | Eseng bakeng sa | |||||||||||||||||

| ozene | oxide | khanya ea letsatsi | mahlaseli | botenya ba lesela | khatello ea maikutlo | axial compression ratio (%) | axial stretch ratio (%) | ho fetoha ha radial (%) | loketseng bakeng sa maro | E chesang H₂SO₄ | E chesang H₂SO₄ | Hot HCL | Hot HCL | E se nang metsi ammonia | NaOH | NaOH | sebetsa mocheso oa mocheso | Max cotinious mocheso o sebetsang | nakoana max mocheso o sebetsang | |||

| lesela + lera la tiiso ea khase | Khatello e ntle | Khatello e mpe | <50% | >50% | <20% | >20% | <20% | >20% | ||||||||||||||

| EPDM rabara (EPDM) | molemo | molemo | molemo | molemo | 0.75 ~ 3.0 limilimithara | boholo ba34.5 mets14.5 | boholo ba34.5 mets14.5 | 60% | 10-20% | 5-15% | khase e senyang metsoako ea manyolo khase e akaretsang | loketseng (e ntle) | karolelano kapa mafutsana | karolelano | mafutsana | loketseng (e ntle) | loketseng (e ntle) | loketseng (e ntle) | -50℃148℃ | 148℃ | 176 ℃ | Aliphatic hydrocarbons Li-hydrocarbon tse nkhang hamonate |

| Rabara ea Silicone(SL) | molemo | molemo | molemo | karolelano | 0.6-3.0 limilimithara | boholo ba34.5 mets14.5 | boholo ba34.5 mets14.5 | 65% | 10%~25% | 5%~18% | khase e akaretsang | mafutsana | mafutsana | mafutsana | mafutsana | mafutsana | loketseng (e ntle) | karolelano | -100℃240℃ | 240 ℃ | 282 ℃ | Oli e qhibilihisitsoeng asiti alkali |

| Chlorosulfonated rabara ea polyethylene (CSM/Hypalon) | molemo | molemo | molemo | molemo | 0.65 ~ 3.0 limilimithara | boholo ba34.5 mets14.5 | boholo ba34.5 mets14.5 | 60% | 10-20% | 5-15% | khase e senyang metsoako ea manyolo khase e akaretsang | loketseng (e ntle) | karolelano | karolelano | mafutsana | karolelano | loketseng (e ntle) | loketseng (e ntle) | -40℃107℃ | 107℃ | 176 ℃ | Hydrogen chloride e kopantsoeng |

| Plastiki ea Teflon (PTFE) | molemo | molemo | molemo | molemo | 0.35-3.0 limilimithara | boholo ba34.5 mets14.5 | boholo ba34.5 mets14.5 | 40% | 5%~8% | 5%~10 | Boholo ba khase e senyang metsoako ea manyolo | loketseng (e ntle) | loketseng (e ntle) | loketseng (e ntle) | loketseng (e ntle) | loketseng (e ntle) | loketseng (e ntle) | loketseng (e ntle) | -250℃260℃ | 260 ℃ | 371℃ | Ho hanyetsa ho apara hampe |

| Fluororubber(FKM)/Viton | molemo | molemo | molemo | karolelano | 0.7-3.0 limilimithara | boholo ba34.5 mets14.5 | boholo ba34.5 mets14.5 | 50% | 10-20% | 5-15% | khase e senyang metsoako ea manyolo khase e akaretsang | loketseng (e ntle) | loketseng (e ntle) | loketseng (e ntle) | loketseng (e ntle) kakaretso | mafutsana | loketseng (e ntle) | karolelano | -250℃240℃ | 240 ℃ | 287 ℃ | ammonia |